Before it won a contract to build the Navy’s new hovercraft, Textron poured $45 million worth of manufacturing robots and other upgrades into its Louisiana shipyard.

“We spent our own funds in order to ensure we put ourselves in a position to win,” said Bill Kisiah, vice president of Textron Systems Marine & Land Systems.

This is increasingly how it works in the military shipbuilding industry. To remain viable players in this market, shipyards are expected to assume more financial risks. Although shipbuilders are private corporations, they depend on the Navy for most of their business, and the Navy is demanding that they put more skin in the game.

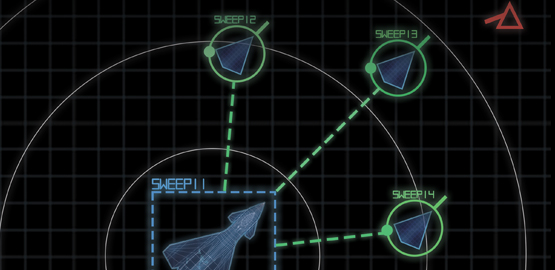

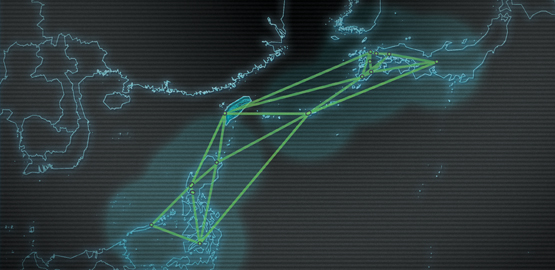

Textron’s investment in its New Orleans yard was probably a safe bet as there is a strong chance the company will continue to build the “ship to shore connectors” that the Navy is buying to replace the fleet of 73 landing craft air cushion vehicles. LCACs shuttle Marines from amphibious warships to the beach.

After a string of massive cost overruns in several ship programs during the past decade, the Navy has shifted to a new business model where the risks are shared by buyers and sellers. This means more private investment, but also a commitment by the Navy to not change ship specs midstream and to curtail admirals’ appetite for exquisite technology.