Nine days after a senior U.S. Navy official told congressional lawmakers the service might need more models of a fighter jet partially constructed in Southern California — the Boeing E/A-18G Growler — the manufacturer held a pro-jet rally Friday at the plant of a Torrance subcontractor.

The goal was to create enough positive good will for the program, which Boeing says supports 20,000 California jobs, to ensure it continues beyond 2016, when the production line is now scheduled to end. Currently, there’s no money in the federal budget to keep the line going, but Boeing officials say they hope public and congressional support will mean a longer life for the Navy’s Growler.

“For me this is a no-brainer,” said state Assemblyman Al Muratsuchi, a Torrance Democrat. “I want to support all of you this morning to make sure we keep all of your jobs here.”

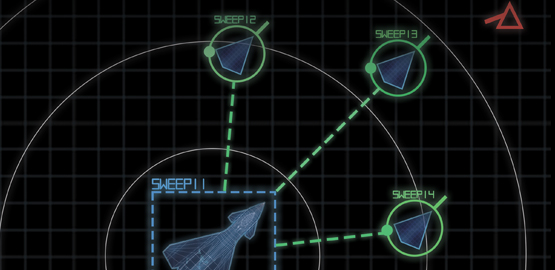

The scene was perfect for public relations purposes. Employees of Moog, a key Boeing subcontractor that makes elements for the Growler wing, were wearing matching black-and-yellow shirts. They cheered at key times when politicians like Torrance Mayor Frank Scotto spoke. Boeing even went so far as to bring a tractor-trailer outfitted with a flight simulator, a prop that allowed Muratsuchi to successfully land on an aircraft carrier. The tractor-trailer is expected to make eight other stops for similar rallies at plants that do subcontracting work.

But for Moog, the situation was not quite as dire as some officials portrayed. David Norman, a New York-based managing director for Moog, which is listed on the New York Stock Exchange, said all of the company’s 630 Torrance employees will keep their jobs regardless of what happens to the Growler program after 2016.

Moog also produces components for other airplanes, including the Boeing 787 passenger jet and the Boeing KC-46 Pegasus, a military refueling and transport aircraft.

“For us, it’s about 15 percent of our business in Torrance,” Norman said of the fighter jet. He said that if the program ends in 2016, the company might have to cease sending work out to some contractors, but he said Moog will not lay off workers.

The airplane is built by Boeing in St. Louis, though 274 of the program’s 800 suppliers are based in California. Money for more of the fighter jets were not in the military’s 2015 budget request given to Congress, and Boeing and its suppliers have known for some time that the end could be coming for the program

But earlier this month, the Navy placed a request for 22 additional Growlers on a list of items it wants but does not have funding for. Since new jets would allow the factory line to stay open, Boeing went into public lobbying mode.

At the rally, Mike Gibbons, Boeing’s vice president for the fighter jet, said the program is worth $1 billion annually in economic impact for the state. “That’s a lot of economic impact for the hotbed of aerospace in the United States,” Gibbons said.

Boeing had long been expected to step aside in favor of the F-35, a new generation of jet built by competitor Lockheed Martin. But that program has had issues, including cost overruns, and there is some concern the jet is not yet as reliable as it should be.

The two airplanes have different capabilities, which is why the Navy expects to retain and update the Growlers through 2040. But it is expected Lockheed Martin will soon become the only manufacturer building new tactical military jets.

The longer the line remains open, Gibbons said, the more chance that Boeing might have to sell to other countries. He said other militaries are considering purchasing the jet, but no country is yet ready to make an order. If the line stays open, even if it makes aircraft for other countries, it will ensure that the United States has two companies capable of building fighters.

“I think we as a nation need to ask ourselves, ‘Are we ready to move toward a future where we have essentially one company developing and building advanced military fighter aircraft?’ ” said Mark Gunzinger, senior fellow at the Center for Strategic and Budgetary Assessments, a Washington, D.C., nonprofit research center. “Or do we want an industrial base where we have competition between two or three companies?”

While this is essentially an issue to be hashed out among Congress, Boeing and the military, Gunzinger said the traveling rallies can work. Both the rallies and the press coverage they generate, he said, can coax senators and members of Congress to add extra money for a special project.

And while the Moog employees will keep their jobs regardless of what happens, some others will not be as lucky.

“I think they do it because it works,” Gunzinger said. “We are talking about people. People have jobs in these industries. There is a defense industrial base that includes some highly skilled people who design and build very advanced military aircraft. The health of that workforce is pretty important to our nation.”