The Defense Department is slowly coming to grips with the situation, said retired Air Force Lt. Gen. Donald J. Wetekam. “We are in unknown territory” on how to keep aircraft flying indefinitely, he said. The Air Force, the branch of the military most affected by aging planes, expects to operate many of its aircraft well beyond their original design service lives. But it does not necessarily know how long components will last, if replacements will be available or if they can be remanufactured, said Wetekam, a senior vice president of AAR Corp., a logistics company that does business in military and commercial aviation.

“We’re in areas where we have not gone before,” he said in a recent interview. When Wetekam first became an officer in the Air Force, the average age of the fleet was nine years. When he retired as deputy chief of staff for installations and logistics, that number had reached 24. Since then, the average age has inched up to 27. “That is three times what it was when I was commissioned. And at the time we didn’t think we had a particularly modern fleet.”

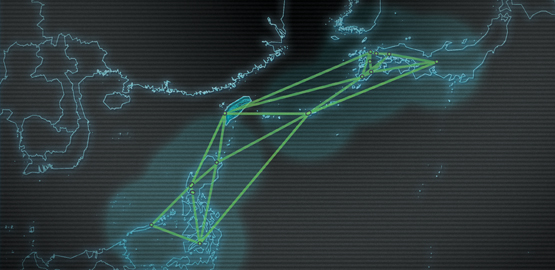

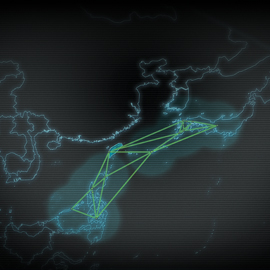

The Defense Department has a fleet of 14,800 aircraft, according to new data by Bloomberg Government. The Air Force has the largest number of fixed-wing aircraft, followed by the Navy. The Army has the largest number of helicopters and surveillance drones.

Air Force Chief of Staff Gen. Mark Welsh sounded alarms in September. “Airplanes are falling apart,” he said. “There are too many things happening because our fleets are too old.”

In a 30-year aircraft procurement plan the Defense Department submitted to Congress three years ago, the Pentagon projected it would be at least 10 years before new strategic airlifters and long-range bombers are produced and delivered. The KC-46A would be the only new airplane procurement though 2025, and the next-generation tactical fighter, the F-35, will not meet required force levels until 2035 at best.

A panel of experts in 2011 warned the Air Force that, in order to cope with its rapidly aging fleet, it needed to revamp aircraft maintenance to make it more efficient and less costly.

“The sustainment of aging aircraft like those in the U.S. Air Force fleet is likely to become a more expensive activity in the next few decades,” said the Air Force Scientific Advisory Board. “It will be important for the Air Force to become as efficient as possible in maintaining and upgrading these aircraft.”

The AFSAB suggested one approach might be to emulate commercial airline practices. “Commercial airlines maintain aircraft much differently than the Air Force,” the panel noted. “They maintain aircraft at flight-capable rates exceeding 90 percent, they do as much repair and maintenance in the field as possible and attempt to minimize depot maintenance.” Unlike the military, commercial airlines have as few aircraft on the ground at the depot as possible because aircraft on the ground do not earn money. “It is a different paradigm than the Air Force where every aircraft costs the service money, whether it flies or not.”

Wetekam agreed that a more commercial approach to aircraft maintenance could save the Pentagon billions of dollars over time, even though there are obvious, fundamental differences between operating military and commercial fleets.

“It would benefit the Defense Department to learn how airline supply chains work,” he said. Airlines have very stringent requirements and, in many cases, they use the exact same equipment that the military employs. Engines are one example. “There are inventive approaches in supporting aircraft and engines that DoD could take better advantage of.” The Air Force has similar engines as commercial airlines but manages its supply chain very differently, Wetekam said. Airlines have a more competitive supply chain for the same type of engine, he added. “Cost is lower based on the fact that they have more competition.”

The Air Force has anywhere from 1,600 to 2,000 CFM56 engines that are widely used around the world, but it maintains a separate supply chain. “There’s an opportunity to adapt a commercial supply chain approach,” he said. The military is beginning to move in that direction, but at a slow pace. “We should leverage the global competitive supply chain marketplace that already exists based on numerous airlines that fly that engine.”

More Boeing 737 derivatives are being used in the military, he said. “Thousands of components in many combat systems are commercial. There should be greater awareness of what systems and components are commercial derivatives,” Wetekam said. “Yes, there are mission differences, but they don’t drive differences in how fleets are sustained.” Too often the mission becomes a scapegoat for adding cost and requirements. An opportunity for savings is when government mechanics are employed to maintain commercial equipment. “Could that be commercialized? Yes, and it could free up more people to work on military-unique equipment.”

The military, nonetheless, will never be as efficient at maintaining airplanes as commercial airlines, for valid reasons, Wetekam said. The Defense Department tends to “over-inspect” aircraft at military bases, and that costs more money and time. “I don’t see that changing.”

Aerospace and defense executives for years have prodded the Pentagon to outsource the maintenance of weapon systems, with promises of huge cost savings. They contend that, if the government provides the right incentives, contractors are able to maintain and upgrade equipment at a much lower cost. One example is the use of “performance based logistics” where the government pays to have “ready to fly” aircraft and it is up to the contractor to make it happen.

Under traditional maintenance contracts, “We get paid to manage the supply chain and to provide parts. But in a performance-based logistics model, we get paid to provide readiness. So the government customer tells us what level of readiness they want and we provide that, and we assume all the risks and all the costs associated with that,” explained Jay DeFrank, vice president of communications and government relations at engine manufacturer Pratt & Whitney.

A study by the consulting firm Deloitte estimated the Pentagon could reduce costs by up to 20 percent by shifting to this model.

In aircraft maintenance alone, the savings could exceed a billion dollars. According to Bloomberg Government, the Defense Department awarded $6.2 billion worth of contracts for aircraft maintenance in fiscal 2013 — $3.7 billion for the Air Force, $1.4 billion for the Army, $1.1 billion for Navy and $31 million for other defense agencies.

Wetekam agrees with proponents of performance-based logistics that it could save money, but the data is fuzzy. “With confusion comes reluctance to come forward with potential savings. These contracts become very difficult to price,” he said. “The value is there. But there’s confusion.

Todd Harrison, senior defense analyst at the Center for Strategic and Budgetary Assessments, said the Pentagon has yet to figure out how to get more efficiency from its contractors. “Under traditional contracts, we pay contractors every time something breaks. Is the incentive for things to break more?” Under a performance-based contract, suppliers would be motivated to invest in components that break less, said Harrison. “It’s a matter of setting up the incentives right.”